Title: Understanding the Purchase Price and Preparation Method of Ceramic Tile 600×600 Introduction: Ceramic tiles have become a popular option for flooring and wall applications due to their durability, versatility, and aesthetic appeal. Among the various tile sizes, the Ceramic tile 600×600 is gaining significant attention in the market. In this article, we will delve into the factors that influence the purchase price of these tiles, as well as the preparation method required before installation. Purchase Price Factors: 1. Tile Quality: The quality of ceramic tiles can vary significantly, impacting the overall purchase price. Tiles manufactured using high-quality materials and advanced production techniques tend to be more expensive but offer superior durability, resistance to wear and tear, and an aesthetically pleasing finish.

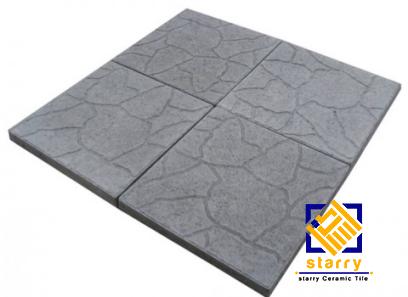

ceramic tile

2. Brand and Reputation: Established brands with a long-standing reputation for producing top-quality ceramic tiles will often charge a premium. These brands invest heavily in research and development and maintain stringent quality control measures, ensuring that their products meet or exceed industry standards. 3. Design and Patterns: Ceramic tiles come in a wide range of designs, patterns, and textures. Intricate designs and patterns require more complex manufacturing processes, which can elevate their price. Additionally, exclusive or custom tile designs may command higher prices due to their uniqueness. 4. Supply and Demand: The principles of supply and demand also affect ceramic tile prices. If there is a high demand for a particular style or brand of ceramic tile with limited availability, the price is likely to increase. Conversely, tiles with lower demand or easily sourced materials may be more affordable.

2. Brand and Reputation: Established brands with a long-standing reputation for producing top-quality ceramic tiles will often charge a premium. These brands invest heavily in research and development and maintain stringent quality control measures, ensuring that their products meet or exceed industry standards. 3. Design and Patterns: Ceramic tiles come in a wide range of designs, patterns, and textures. Intricate designs and patterns require more complex manufacturing processes, which can elevate their price. Additionally, exclusive or custom tile designs may command higher prices due to their uniqueness. 4. Supply and Demand: The principles of supply and demand also affect ceramic tile prices. If there is a high demand for a particular style or brand of ceramic tile with limited availability, the price is likely to increase. Conversely, tiles with lower demand or easily sourced materials may be more affordable.

Specifications of ceramic tile

Preparation Method: 1. Surface Preparation: Prior to installing ceramic tiles, it is crucial to prepare the underlying surface properly. This involves removing any existing flooring or wall coverings, leveling the substrate, and ensuring it is clean, dry, and free of debris. A smooth and level surface will prevent the formation of lumps or unevenness during the tile installation process. 2. Acclimatization: Ceramic tiles should be acclimatized to the room in which they will be installed to minimize the risk of future problems. This involves storing the tiles in the designated space for at least 48 hours prior to installation, allowing them to adjust to the temperature and humidity conditions of the room. 3. Layout and Spacing: Careful planning of the tile layout is essential for a visually pleasing and structurally sound installation.

Preparation Method: 1. Surface Preparation: Prior to installing ceramic tiles, it is crucial to prepare the underlying surface properly. This involves removing any existing flooring or wall coverings, leveling the substrate, and ensuring it is clean, dry, and free of debris. A smooth and level surface will prevent the formation of lumps or unevenness during the tile installation process. 2. Acclimatization: Ceramic tiles should be acclimatized to the room in which they will be installed to minimize the risk of future problems. This involves storing the tiles in the designated space for at least 48 hours prior to installation, allowing them to adjust to the temperature and humidity conditions of the room. 3. Layout and Spacing: Careful planning of the tile layout is essential for a visually pleasing and structurally sound installation.

buy ceramic tile

This includes determining the positioning and orientation of the tiles, as well as the spacing between each tile. Generally, a minimum grout joint width of 3mm is recommended for ceramic tiles. 4. Substrate Priming: Depending on the substrate, priming may be required before tile installation. Primers help improve adhesion and minimize the risk of moisture-related issues, such as tile delamination or the growth of mold and mildew. Conclusion: When considering purchasing ceramic tiles of the size 600×600, it is important to take into account factors like tile quality, brand reputation, design complexity, and supply-demand dynamics. Additionally, proper surface preparation, acclimatization, layout planning, and substrate priming are crucial steps in achieving a successful tile installation. By understanding these factors and employing the recommended preparation methods, you can ensure a long-lasting, visually appealing, and functional ceramic tile installation.

This includes determining the positioning and orientation of the tiles, as well as the spacing between each tile. Generally, a minimum grout joint width of 3mm is recommended for ceramic tiles. 4. Substrate Priming: Depending on the substrate, priming may be required before tile installation. Primers help improve adhesion and minimize the risk of moisture-related issues, such as tile delamination or the growth of mold and mildew. Conclusion: When considering purchasing ceramic tiles of the size 600×600, it is important to take into account factors like tile quality, brand reputation, design complexity, and supply-demand dynamics. Additionally, proper surface preparation, acclimatization, layout planning, and substrate priming are crucial steps in achieving a successful tile installation. By understanding these factors and employing the recommended preparation methods, you can ensure a long-lasting, visually appealing, and functional ceramic tile installation.

Your comment submitted.